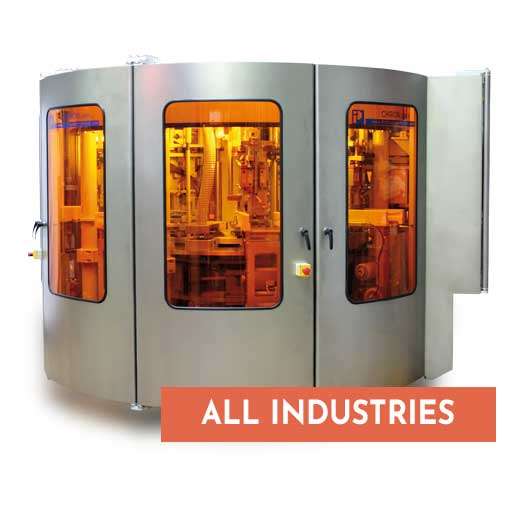

CHEIRON

FLEXIBILITY FOR MULTIPLE PROCESSES

The Cheiron is an automatic pad printing machine dedicated to the medical device industry. Because more positions (4-16) are available, more manufacturing processes can be incorporated in the machine. As such it cannot be seen as merely a pad printing machine. From assembly to packaging, everything is possible.

- Automatic feeding

- Compliant to medical device USP class VI

- All-in-one machine: assembly – printing – packaging

HMI remote position

Automatic feeding: hopper, vibrating bowl, linear vibration, rotary table.

Product handling: jig, vacuum, …

Assembly

Pre-treatment: hot/cold air, plasma, flame, corona, UV, ionisation.

Pad printing

Automatic pad cleaning

Post-treatment: IR, NIR, hot air.

Camera inspection: print, assembly, orientation, tray full/empty.

Rejection: individual, batch, product samples.

Reporting: machine KPI, batch sampling.

Product transport: rotary table, LTS shuttle, linear shuttle, belt driven indexer.

ROTA

The ROTA setup is used when the number of working stations is limited and it is important to have good accessibility to all parts of the machine. By placing the working stations outside of the product trajectory each module can easily be reached by hand during production.

LINO

The LINO setup is used to maximize the number of working stations. By placing it in a line it is possible to add feature after feature. This setup also allows great accessibility from all sides.

RING

The RING setup is used when production space is limited and machine design needs to be as compact as possible. By placing all working stations inside the product trajectory we save a lot of space, but it also makes it harder to access certain parts during production.

Fast change-over

Clean room approved

Siemens OEM Partner

Compliant to

ORION

flexibility for multiple processes

| Automatic | Pneu/servo |

| 1-6 ink cups | up to 12 000 pcs/h |

Download technical sheet

Please fill in your contact details