Product manager - Validation officer

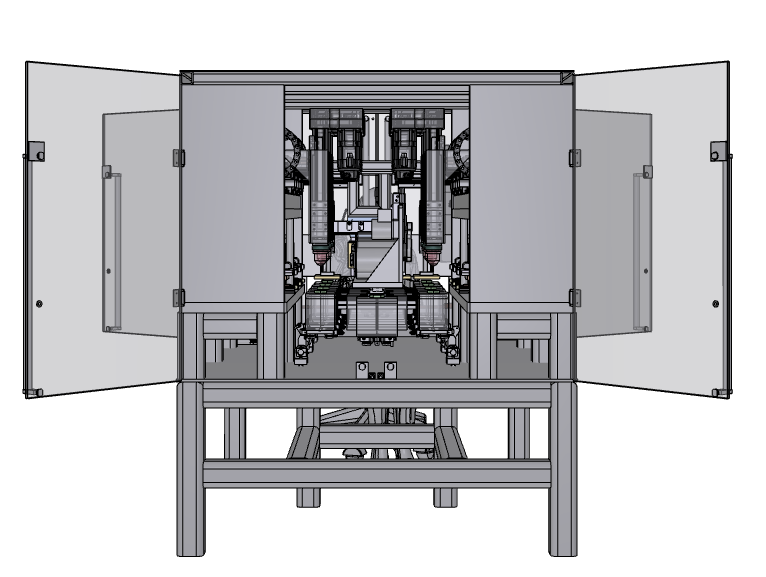

We, a high-tech machine manufacturer based in Aalter, specialise in the design, production and commissioning of printing machines using the pad printing process. We also supply all accessories, including inks, printing plates and printing pads.

Our customers are global players in the fields of pharma, food, medical devices, but also cosmetics, toys and automotive.

We are proud of our status as Siemens OEM partner from the very beginning.

Everyone @PI does their bit to achieve our goals. Customer satisfaction requires commitment from everyone and the will to want to accelerate that last metre. “Teamwork makes the dream work” could be our slogan.

WHAT DO WE OFFER?

As part of the team, you are the driving force behind the development and success of our products/projects. You are responsible for the entire process from development to delivery, checks, releases and further optimisation.

In addition, you are responsible for coordinating and executing the Validation Master Plan (to be executed per product/project).

In addition, you are also the central point of contact for all activities linked to CAPA for drawing up and implementing improvement projects in the context of product and project optimisations. This requires intensive cooperation with the various internal departments.

The printing machines for pharma and medical devices purposes need to be validated whereby we follow the GAMP5 validation model. The machine data comply with ALCOA principles, including 21 CFR part 11 compliancy.

A machine is divided into a project part (related to the customer’s product) and a product part (the machine, including its software), with each part being validated separately in its own way, but also together.

You are in direct contact with After-Sales Service, Engineering, Production and QA.

Naturally, we offer a market-compliant remuneration.

YOUR RESPONSIBILITIES

- Independently establish and document a risk-based validation strategy

- Drafting and executing Validation Master Plans and corresponding Validation Product and Project Plans

- Elaborating product and project validation miv any process validation, software validation, …

- Drawing up validation documentation in accordance with the guidelines

- Identifying and implementing efficiency follow-up tools

- Drafting changes in the context of CAPA with identification of improvements and working out an action plan

- Coordinating proposals with stakeholders

- Performing complex data analyses in Excel in the context of (root-cause analysis and) optimisations

- Supporting and training problem-solving techniques to other departments

- Investigating urgent and critical problems relating to the product or production process (whether or not in the context of incident handling)

YOUR PROFILE

- Higher education in science/engineering

- Experience in similar position

- Excellent knowledge of Microsoft Outlook, in particular Word and Excel (data analysis)

- You are Dutch-speaking with a good knowledge of English

- Good knowledge of GMP and experience in a GMP environment

- Experience in root-cause analysis (DMAIC, FMEA, 6M), knowledge of lean and/or six sigma is a plus

- Excellent project management skills: elaborate planning, follow up activities and escalate issues/risks in time

- Excellent technical writing skills: documenting information concisely but completely and clearly in a clear/structured manner

- Strong interpersonal skills (communicative and willing to listen): able to gather the necessary information and strictly follow up on actions in other departments

- Strong analytical skills: quickly form a coherent picture and define action plan

- Great sense of quality and detail

- Identify with Printing International’s Vision & Mission

PERSON-RELATED COMPETENCES

- Critical thinking

- Responsibility

- Analysing

- Working together