PAD PRINTING MACHINE

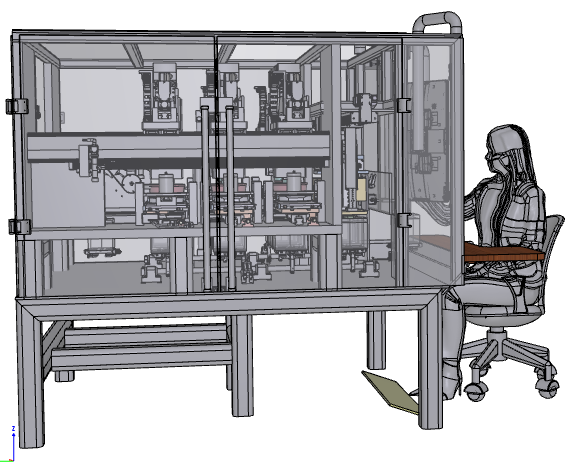

MANUAL PAD PRINTING MACHINE

Explore a wide selection of pad printing machines (also known as tampography machines) designed for straightforward operation and unparalleled print quality. Our machines are suitable for any material and surface, ensuring your unique requirements are met with precision and ease.

Our pad printing machines offer exceptional repeatability and precision, guaranteeing superior print quality every time. Perfect for both small and irregularly shaped objects, our pad printers consistently deliver outstanding results.

AGATE LABO

pad printing machine for research & development

| Manual | Pneumatic |

| 1 ink cup | up to 20 000 pcs/h |

AUTOMATIC PAD PRINTING MACHINE

Our automatic pad printing machine is engineered to provide top-tier pad printing with unbeatable precision and consistency. Using advanced patented technology, these high-speed pad printers guarantee remarkable repeatability and speed, making them perfect for various industries such as medical devices and pharmaceuticals.

The sophisticated design of our automatic pad printing machine ensures optimal performance and consistently delivers high-quality prints. Enjoy reliable and efficient pad printing solutions tailored to achieve exceptional results every time.

Optimize your production process today with our automatic pad printing machine—the ultimate choice for precision and efficiency in pad printing.

ROTARY PAD PRINTING MACHINE

Rotary Pad Printing Machine specialize in delivering high-quality prints on cylindrical objects. These machines are equipped with a rotating mechanism that facilitates continuous, seamless printing around the entire circumference of an item. This technology ensures precision and consistency, making it ideal for decorating bottles, tubes, and other rounded products.

By using Rotary Pad Printing Machine, businesses can achieve efficient and accurate printing, enhancing the visual appeal and functionality of their cylindrical goods. This method is particularly valued in industries where exactness and uniformity in printing are crucial.