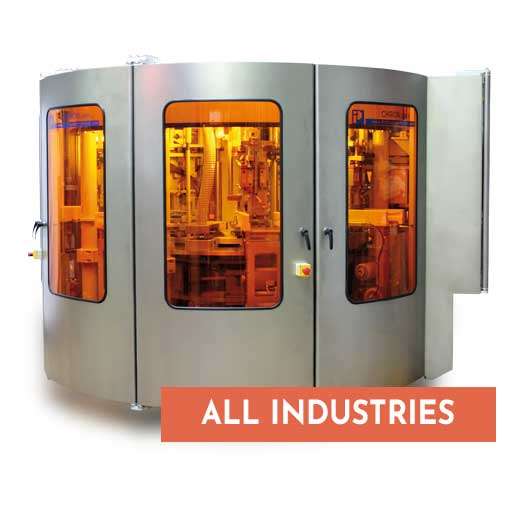

CHEIRON LINOSYSTEM

Flexibility/ High quality multi-colour printing

The Cheiron Linosystem is an automatic or manual pad printing machine intended for all industries. Choose the solution that suits your needs, depending on the capacity you require.

As multiple positions (1-16) are available, multiple production processes can be incorporated into the machine. The machine offers multi-color printing (in CMYK) at the highest resolution.

Can be complemented by camera inspection and rejection systems.

- Constant high print quality

- Automatic feeding

- Fast changeover for consumables and products

- Standard modules (availability spare parts)

- Optimal ergonomy (low noise level, working heights, machine interface, safety, easy to operate…)

- Quick design setup

- Siemens components (Printing International is certified Siemens OEM partner)

HMI remote position

Automatic feeding: hopper, vibrating bowl, linear vibration, rotary table.

Product handling: jig, vacuum, …

Assembly

Pre-treatment: hot/cold air, plasma, flame, corona, UV, ionisation.

Pad printing

Automatic pad cleaning

Post-treatment: IR, NIR, hot air.

Camera inspection: print, assembly, orientation, tray full/empty.

Rejection: individual, batch, product samples.

Reporting: machine KPI, batch sampling.

Product transport: rotary table, LTS shuttle, linear shuttle, belt driven indexer.

LINO

The LINO setup is used to maximize the number of working stations. By placing it in a line it is possible to add feature after feature. This setup also allows great accessibility from all sides.

Fast change-over

Closed ink cups

Siemens OEM Partner

Compliant to

ORION

flexibility for multiple processes

| Automatic | Pneu/servo |

| 1-6 ink cups | up to 12 000 pcs/h |

Download technical sheet

Please fill in your contact details