Without these elements, pad printing is impossible. It is important that they are of the highest quality

Pad printing, also called tampography or tampo printing, is an indirect offset (gravure) printing process where a silicon pad takes a 2-D image from a laser engraved (etched) printing plate (also called cliché) and transfers it to a 3-D object. Thanks to pad printing, it is now possible to print all kind of difficult shaped products such as curved (convex), hollow (concave), cylindrical, spherical, compound angles, textures, etc. which were not available with traditional printing processes.

Step 1: The closed (sealed) ink cup sits over the engraved (etched) artwork area of the pad printing plate, covering the image and filling it with ink. This is called the home position.

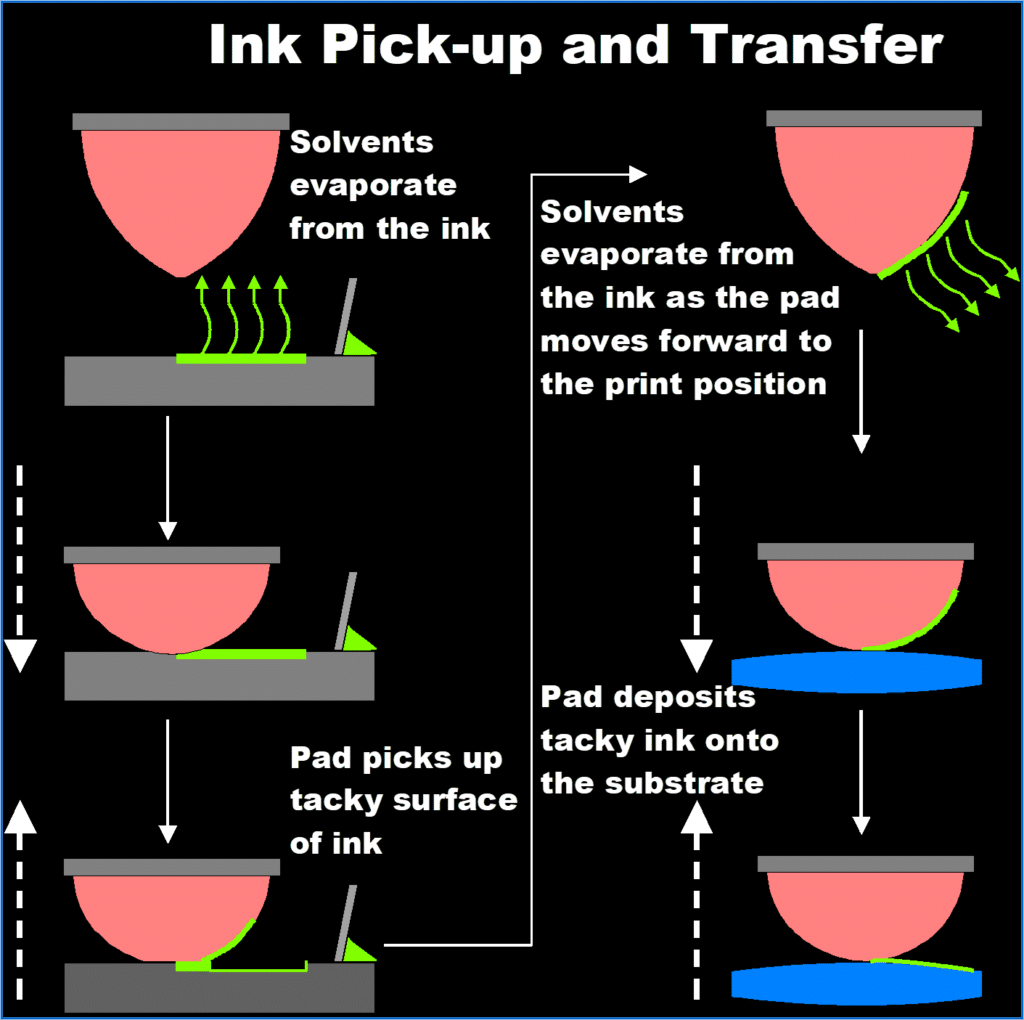

Step 2: The closed ink cup moves away from the engraved artwork area, taking all excess ink and exposing the engraved image, which is filled with ink. The top layer of ink becomes tacky as soon as it is exposed to the air; that is how the ink adheres to the transfer pad and later to the product to be printed.

Step 3: The transfer pad presses down onto the printing plate momentarily. As the pad is compressed, it pushes air outward and causes the ink to lift (transfer) from the engraved artwork area onto the pad.

Step 4: As the transfer pad lifts away, the tacky ink film inside the engraved artwork area is picked up on the pad. A small amount of ink remains in the pad printing plate.

Step 5: As the transfer pad moves forward, the ink cup also moves to cover the engraved artwork area on the printing plate. The ink cup again fills the engraved artwork image on the plate with ink in preparation for the next cycle.

Step 6: The transfer pad compresses down onto the product, transferring the ink layer picked up from the printing plate to the product surface. Then, it lifts off the substrate and returns to the home position, thus completing one print cycle.

Our high-quality pad printing machines are designed for easy operation and deliver exceptional print quality. Whether you’re printing on plastic, glass, metal, or any other material, our pad printers ensure excellent performance on any surface.

Pad printing is used for printing on difficult products in many industries. Printing International focuses especially on specific product groups, such as:

Check out most common problems and solutions.

Download our troubleshooting guide and find advice from our pad printing experts.

Versatility: Capable of printing on various shapes, sizes, and materials.

Precision: Delivers high-resolution prints on small, intricate, or uneven surfaces.

Efficiency: Suitable for both small runs and large-scale productions.

Customization: Easily accommodates different designs and colors with quick changeovers.

Pad printing can also be used to transfer functional materials such as conductive inks, adhesives, flavours, nutritional additives, natural dyes and lubricants.

Conductive inks:

Advances in conductive ink technology – including ethyl-cellulose polymers, carbon/graphite, silver or UV curable dielectric inks – allow for pad printing circuit boards, multi-layer membrane switches, and touch-key applications, among other uses.

Benefits include savings in process and materials cost, such as doing away with etched copper, gold plating or soldered wire. For example, replacing gold plating with a carbon ink has proven greater robustness over that extremely expensive metal, and a lower electrical resistance than copper.

A growing economic sector is using conductive inks for Radio Frequency Identification (RFID), which is rapidly streamlining inventory and shipping in the global marketplace. Other applications for conductive inks include medical sensors, transistors, antennas, and electrodes; shielding against electro-magnetic and radio-frequency interference plus dissipating or eliminating static.

Once again, pad printing’s ability to print on uneven, curved or recessed surfaces gives the technology an advantage over standard flatbed methods of materials deposition. However, as with printing adhesives, conductive inks must be solvent based and neither too aqueous nor too hydrophilic to be effectively transferred with pad printing.

Adhesives:

Applying adhesives is considered by many manufacturers to be a time-consuming and labour-intensive process. Small or translucent parts need precision application, which often drives up the bottom line. When factored in with waste and clean up, alternative methods of adhesive application are much sought after. Adhesive film is one method, but also results in waste materials. Pad printing’s transfer method of precise viscous liquid deposition is the ideal solution. A sealed ink cup keeps the glue from drying out, and the printing plate can be engraved to the desired depth and exact line thickness (or thinness).

Once adjusted, the pad then deposits exactly the same amount of adhesive in exactly the same location every time. As part of an in-line automated process, the finished part – for example a bevelled cell phone lens – can be fed into a custom machined shuttle fixture that holds the part in place while glue is applied to its edge. The lens is then conveyed to a pick-and-place robot arm that sets the cell phone body onto the glued area. Further automation can transfer the joined parts onto another conveyor that transports them through a drying tunnel or further down the assembly line. Ultraviolet or heat-cured adhesives are useable with this process, as are many solvent-based glues that aren’t too aqueous or hydrophilic.

Flavours, nutritional additives and natural dyes:

Pad printing on foodstuffs is another area that is only beginning to see its potential being explored. More than just a high-tech way to decorate cookies with natural dyes, pad printing technology could be used to apply flavours or nutritional additives to receptive food surfaces. The pads used in pad printing are of variable hardness’s, so the end user can choose the “durometer” of their pad depending upon the strength of the substrate. For example, a gumball would use a harder pad to wrap 180° around, while printing a flavour into the hollow of an antacid would need a softer pad, so as not to crush the tablet.

Lubricants:

Another exacting and hands-off use for the pad printing of fluids are lubricants. Again, this is an area where precision can be challenging, and waste is costly and messy. Without re-inventing the manufacturing process by integrating new and different materials such as powdered or dry film lubricants (and their associated unknown problems, costs and technologies), pad printing provides a simple, proven mechanical solution.

Whether it’s an oil, grease or other substance that reduces friction: if it can stick to a silicon pad and can be transferred to another substrate – it can be pad printed. Since pad printing is well suited for use on three-dimensional items, such as hinges, bearings, threaded parts and housings. Any production line that manufactures similar components can integrate this technology into the process. Especially where misapplication can cause catastrophic failure of adjacent mechanisms, precise lubricant application can be achieved with pad printing & whether it be miniscule dots, fine lines and squiggles or exact angular confinement.

Subscribe to our monthly newsletter. Delivered directly to your inbox.

With the fast pace of medical and technological design advances, finding a tool that bridges the past and future is critical, both on the manufacturing floor and in budget meetings. Pad printing is a tried and true technology that is flexible enough to adapt to a vast variety of substrates and substances. The need to customize materials deposition will only increase as market niches continue to increase and narrow.

Designers, manufacturers, engineers and managers would be well served to explore the ways pad printing can be used for non-decorating, non-identifying purposes. It’s proven that the best tool is one with many uses and ideal for turning a problem into a solution: just add a full measure of creativity and a spark of imagination.